sales.shreewire@gmail.com - GST NO. : 27AAYCS8715M1Z9

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Mixing Products Into Water Or Water-like Fluids,Used For Low Viscosity |

| Material | SS - 316 |

| Model Type | Blade Design Mixer |

| Click to view more | |

Product Details

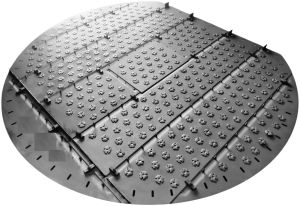

Model Type – 1: Blade Design Mixer

-

Mixer Type: SS – 316 Material

-

Viscosity Range: Less than 1500 cps

-

Reynolds Number: Greater than 500

-

Size Range: ½" to 14"

-

Application: Mixing products into water or water-like fluids

SW-SMx-01: Used for low viscosity. The faster the fluid moves, the faster the mixing. Ideal for mixing products into water or water-like fluids.

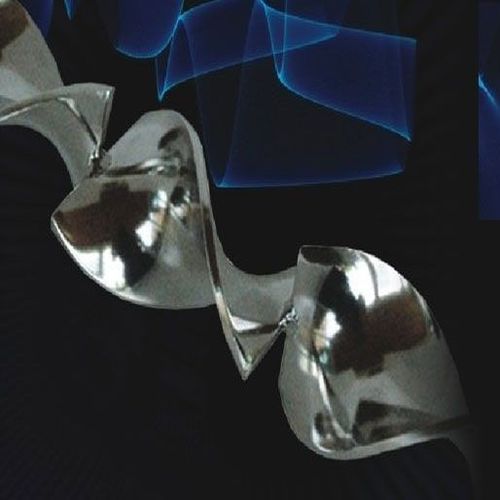

Model Type – 2: Helical Design Mixer

-

Model: SW-SMx-02

-

Application: Used for high viscosity blending and when the fluid moves more slowly through the mixer

-

Material: SS – 316

-

Viscosity Range: Greater than 1500 cps

-

Reynolds Number: Less than 500

-

Size Range: ½" to 14"

-

Application Areas: Epoxy blending, fruits into yogurt, cookies into ice cream, thermal homogeneity, slurry suspension, folding/stripping

Customer Benefits

-

Excellent mixing and dispersing, even with widely differing fluid viscosities

-

Compact designs

-

Reduced product degradation due to very short residence time

-

Mixing of sensitive products under minimal shear stress

-

No deposits and blockages due to excellent cross-mixing

Advantages

-

High level of mixing efficiency – formation of byproducts is dramatically reduced

-

Low energy consumption

-

Easy installation

-

Available in all standard pipe sizes, and for open channel designs, available in any size with no upper limit

Industries Served

-

Pulp and Paper Processing

-

Pharmaceuticals

-

Oil Refining

-

Petrochemicals

-

Food Processing

-

Natural Gas Processing

-

Water and Waste Water Treatment

Design Calculations

Reynolds Number Formula:

Re = Dvρ/µ

Number of Elements Required:

-

Re < 10 → 24–36 elements

-

10 < Re < 100 → 18 elements

-

100 < Re < 1000 → 12 elements

-

1000 < Re < 10000 → 6 elements

-

Re > 10000 → 4 elements

Pressure Drop Calculation

ΔP = 3.061 × 10⁶ × f × n × smxpx(u)² × E

G Value Calculation

G = v(hf × g × ρ / μt)

Pipe Diameter (D in meters)

D = √(4Q / πv)