sales.shreewire@gmail.com - GST NO. : 27AAYCS8715M1Z9

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Mist Eliminators |

| Material | Metal Wire Or Plastic Monofilaments |

| Efficiency | Up To 99% For Particles As Small As 5 Microns |

| Click to view more | |

Product Details

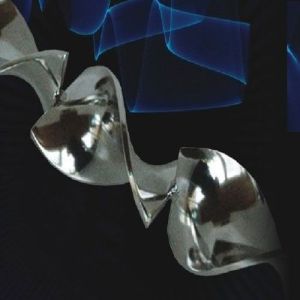

Shreewire Mist Eliminator is a static, in-line separation device fabricated in pad form from symmetrical interlocking loops of knitted metal wire or plastic monofilaments. With high free volume and a large impingement surface area, the mist eliminator ensures separation efficiency of up to 99% for particles as small as 5 microns, while maintaining a low pressure drop around 25 mm WC.

It can be installed in new or existing process vessels—such as evaporators, scrubbers, and pressure vessels—without the need for special housing. It is virtually maintenance-free, requiring only occasional cleaning in fouling service.

How Does the Shreewire Mist Eliminator Work?As vapor carrying entrained liquid droplets or mist passes through the Shreewire Mist Eliminator, the vapor moves freely through the layered mesh. The droplets, having greater inertia, impact the wire surface and are temporarily held. As they collect and coalesce, they grow larger and eventually drain back into the system. The result is an overhead vapor stream that is nearly free of liquid.

Efficiency and Performance-

Removes droplets down to 5 microns

-

Separation efficiency up to 99%

-

Available in multiple mesh styles and materials

-

Pressure drop typically less than 25 mm WC; around 5 mm WC in vacuum service

-

Special high-efficiency designs available upon request

Shreewire Mist Eliminators are suitable for a wide range of industrial applications, including:

-

Distillation Equipment

-

Knockout Drums

-

Scrubbers

-

Absorbers

-

Evaporators

-

Vacuum Towers

-

Steam Drums

-

Strippers and Regenerators

The selection and sizing of a Shreewire Mist Eliminator depends on several factors:

-

Gas or vapor flow rate and entrained liquid content

-

Droplet size distribution and separation efficiency required

-

Allowable design velocity

-

Physical and chemical properties of the gas and liquid phases

-

Material of construction

The mist eliminator consists of a wire mesh pad sandwiched between a top hold-down grid and a bottom support grid. These grids are specially designed with a high percentage of open area to minimize pressure drop.

Key installation requirements:

-

The pad is slightly oversized to ensure a tight fit within the vessel

-

A 50 to 75 mm wide annular support ring, drilled with 3 to 6 mm diameter holes, should be welded to the vessel wall

-

The pad and grid assembly is secured using 2 mm diameter tie wires or spacer pipes with appropriate bolts and fasteners

-

Intermediate support beams are recommended for spans larger than 1800–2000 mm