sales.shreewire@gmail.com - GST NO. : 27AAYCS8715M1Z9

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Column Packing |

| Material | SS 304 And SS 316 |

| Color | Metallic |

| Click to view more | |

Product Details

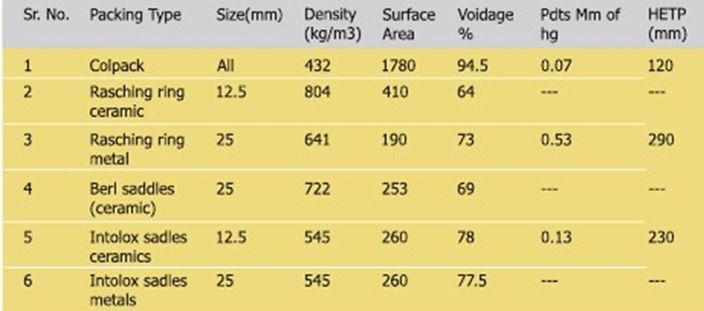

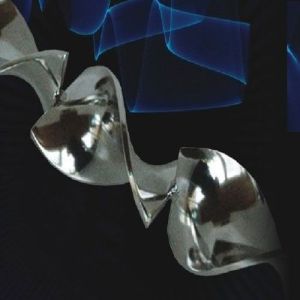

Colpack has, over the years, become generally accepted as the most efficient packing for distillation towers operating at reduced pressure. It is ideal for the separation of heat-sensitive and close-boiling fractions, where many theoretical stages and low pressure drop are required. Colpack offers a precise solution to this challenge.

ConstructionColpacks are fabricated by knitting bunched fine wires of filaments (0.01 mm), which are then crimped and wound into rolls of the desired column diameter.

Any material that can be drawn into fine wire or filament may be used, but SS 304 and SS 316 are commonly stocked. Higher alloys are available upon request.

-

Supplied as 150 mm high packings, matching the nominal bore of the column.

-

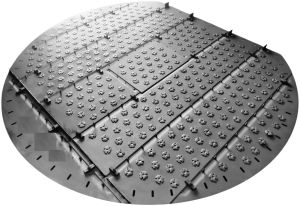

Requires only simple support—typically two bars at right angles or parallel bars (6-inch spacing) for large towers.

-

Packed from the top, ensuring the tower is free of internal projections.

-

Push gently down to the support grid using a wooden disc mounted on a pole to prevent damage.

-

Alternate crimp directions should be maintained for optimal performance.

-

Easily retrofitted to existing columns by replacing random packing, leading to:

-

Improved product quality

-

Higher production capacity

-

Lower pressure drop

-

-

Low bulk density (432 kg/m³) results in:

-

Lighter columns

-

Reduced structural foundation needs

-

Lower insulation, piping, and installation costs

-

Possible column diameter reduction

-

-

High voidage allows free flow of liquid and vapor, leading to:

-

Extremely low pressure drop per unit height

-

-

High surface area (1780 m²/m³) enables:

-

Intimate vapor-liquid contact

-

Lower HETP values

-

-

HETP < 15 cm over the entire velocity range

-

Flooding velocity is 2 to 2.5 times higher than conventional packings, allowing:

-

Smaller column diameters or

-

Increased throughput

-

-

Vacuum distillation, where pressure drop is critical and high separation efficiency is needed.

-

Thermal-sensitive component separation.

-

Very low superficial velocities (as low as 0.1 cm/sec).

-

Pollution control, especially in the biological oxidation of liquid effluents.

-

Manufacture of organic compounds.

-

Outperforms conventional packings in both performance and reliability.