sales.shreewire@gmail.com - GST NO. : 27AAYCS8715M1Z9

Column Internals & Tower Packing

Leading Manufacturers, Exporters and Wholesaler of Bed Limiter, Distillation Collector, Distillation Column Internals Sieve Tray, Distillation Distributor, Knitted Column Packing, Knitted Wire Mesh Washer, Metallic Random Packing, Packed Column, Stainless Steel Structured Packing, Static Mixer, Stripper Column, Support Grid and Tower Packing from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Steel |

| Color | Silver |

| Application | Prevents Pillows From Falling Off The Bed |

| Dimensions | Standard Size To Fit Most Bed Frames |

| Weight | Lightweight For Easy Handling |

| Care Instructions | Wipe Clean With A Damp Cloth |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Distillation Collector |

| Material | Stainless Steel |

| Color | Silver |

| Packaging | Box |

| Application | Collecting Distilled Liquids |

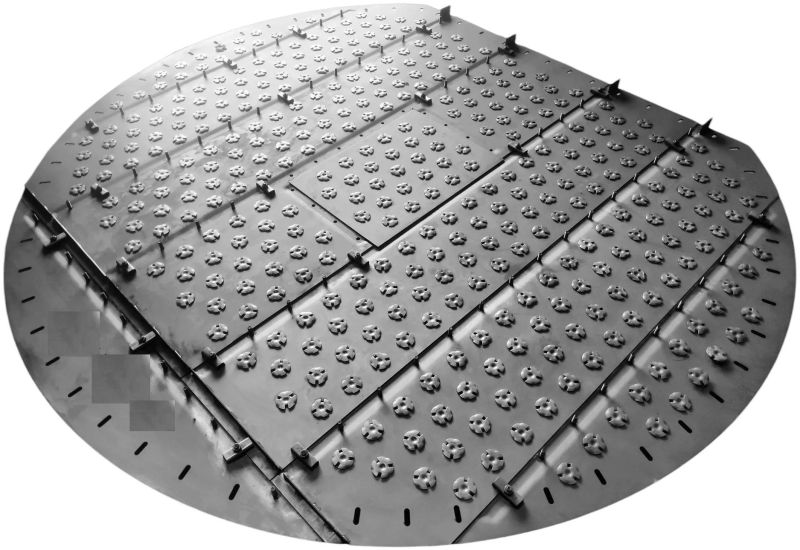

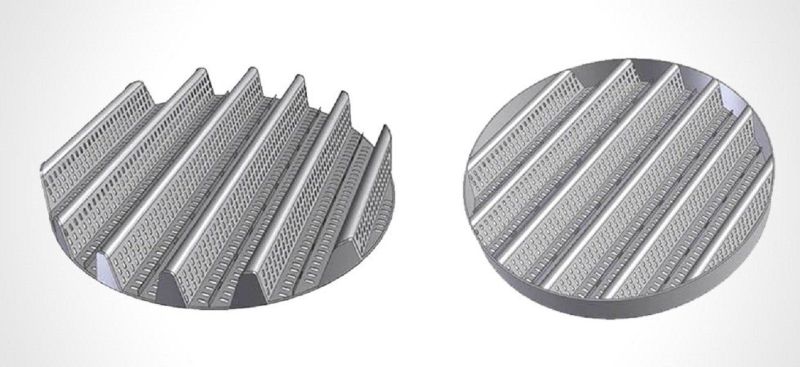

| Business Type | Manufacturer, Exporter, Supplier |

| Product Type | Distillation Column Internals Sieve Tray |

| Material | Stainless Steel |

| Color | Silver |

| Packaging | Standard Packaging |

| Application | Separation Of Liquid Mixtures In Distillation Processes |

| Shape | Rectangular Or Circular |

| Compatibility | Suitable For Use In Various Distillation Columns |

| Installation | Easy To Install And Replace |

| Maintenance | Regular Cleaning Recommended |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Industrial Equipment |

| Material | Stainless Steel |

| Color | Silver |

| Packaging | Secure Packaging For Safe Delivery |

| Usage | Used In Distillation Processes To Distribute Liquid Evenly Across The Column |

| Size | Standard Size For Compatibility With Common Distillation Setups |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Column Packing |

| Material | SS 304 And SS 316 |

| Color | Metallic |

| Packaging | Rolls |

| Usage/Application | Distillation Towers |

| Construction | Knitted Bunched Fine Wires |

| Height | 150 Mm |

| Support | Simple Support With Two Bars At Right Angles Or Parallel Bars |

| Installation | Packed From The Top |

| Salient Features | Easily Retrofitted, Low Bulk Density, High Voidage, High Surface Area |

| Applications | Vacuum Distillation, Thermal-sensitive Component Separation, Pollution Control |

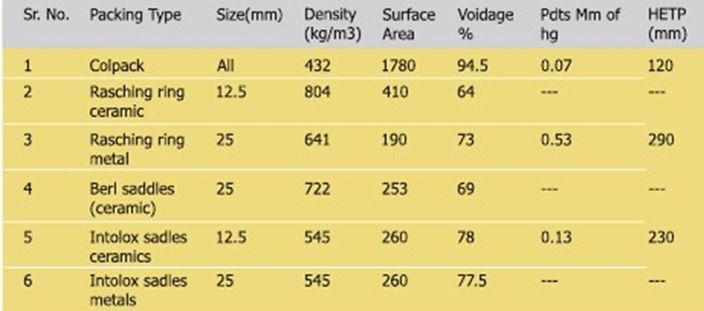

Colpack has, over the years, become generally accepted as the most efficient packing for distillation towers operating at reduced pressure. It is ideal for the separation of heat-sensitive and close-boiling fractions, where many theoretical stages and low pressure drop are required. Colpack offers a precise solution to this challenge.

ConstructionColpacks are fabricated by knitting bunched fine wires of filaments (0.01 mm), which are then crimped and wound into rolls of the desired column diameter.

Any material that can be drawn into fine wire or filament may be used, but SS 304 and SS 316 are commonly stocked. Higher alloys are available upon request.

-

Supplied as 150 mm high packings, matching the nominal bore of the column.

-

Requires only simple support—typically two bars at right angles or parallel bars (6-inch spacing) for large towers.

-

Packed from the top, ensuring the tower is free of internal projections.

-

Push gently down to the support grid using a wooden disc mounted on a pole to prevent damage.

-

Alternate crimp directions should be maintained for optimal performance.

-

Easily retrofitted to existing columns by replacing random packing, leading to:

-

Improved product quality

-

Higher production capacity

-

Lower pressure drop

-

-

Low bulk density (432 kg/m³) results in:

-

Lighter columns

-

Reduced structural foundation needs

-

Lower insulation, piping, and installation costs

-

Possible column diameter reduction

-

-

High voidage allows free flow of liquid and vapor, leading to:

-

Extremely low pressure drop per unit height

-

-

High surface area (1780 m²/m³) enables:

-

Intimate vapor-liquid contact

-

Lower HETP values

-

-

HETP < 15 cm over the entire velocity range

-

Flooding velocity is 2 to 2.5 times higher than conventional packings, allowing:

-

Smaller column diameters or

-

Increased throughput

-

-

Vacuum distillation, where pressure drop is critical and high separation efficiency is needed.

-

Thermal-sensitive component separation.

-

Very low superficial velocities (as low as 0.1 cm/sec).

-

Pollution control, especially in the biological oxidation of liquid effluents.

-

Manufacture of organic compounds.

-

Outperforms conventional packings in both performance and reliability.

| Business Type | Manufacturer, Exporter, Supplier |

| Wire Diameter | 0.08 To 0.5mm |

| Application | Applications Include Knitted Mesh Rolls,Demister Mist Eliminators,Clear-mesh,Anti-vandal Mesh,Grease Filters,Framed Filters,Anti-Vibration Mounts,Heavy-Duty Seals,RFI / EMI Shielding,Vibration And Shock Absorption,Air And Liquid Filtration,Nois |

| Material | Stainless Steel Grades: AISI 302,304,316L,321,309,314,310S |

| Number Of Flower | Knitted Wire Mesh |

| Stitch | Number, Shape, And Size Customizable |

| Form | Filters, Oil And Air Breather Elements, Catalytic Converter Mesh, Insulator Blanket Mesh, Mufflers And Silencers, Copper Mesh Oil-Bath Separators, Mist Elimination Pads, Ground Wire Mesh |

Shreewire’s Knitted Mesh Products

Shreewire produces a high-quality, versatile knitted mesh using a wide range of materials, offering a high degree of creativity and expertise. Our skilled design and development team ensures that the correct characteristics and specifications are chosen for each individual application. Customizable features include wire diameter (0.08 to 0.5mm), as well as the number, shape, and size of the stitch.

The majority of materials we use are 100% recyclable, addressing growing global concerns across various industries. With access to a vast selection of raw materials, we offer expert guidance to ensure optimum performance and long life expectancy in nearly any application.

Materials Readily Available:

Stainless Steel Grades: AISI 302, 304, 316L, 321, 309, 314, 310S

Materials Available on Demand:

Super Alloys: Inconel 601, Incoloy DS, Hastelloy, Carpenter 20, Monel

Others: Aluminium, Copper, Brass, Mild Steel (Plain and Galvanized), Polypropylene

And other continuous filament materials supplied as wire or yarn

Applications:

Knitted Mesh Rolls

Demister Mist Eliminators

Clear-mesh

Anti-vandal Mesh

Grease Filters and Framed Filters

Anti-Vibration Mounts

Heavy-Duty Seals

RFI / EMI Shielding

Vibration and Shock Absorption

Air and Liquid Filtration

Noise Suppression

Heat Transfer and Insulation

Mist Elimination and Process Separation

Flame Arrestors

Engine Catalysts

Knitted Wire Mesh Forms:

Filters

Oil and Air Breather Elements

Catalytic Converter Mesh

Insulator Blanket Mesh

Mufflers and Silencers

Copper Mesh Oil-Bath Separators

Mist Elimination Pads

Ground Wire Mesh

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Random Packing |

| Material | Metallic |

| Color | Silver |

| Packaging | Usually Packed In Cartons Or Wooden Cases. |

| Usage | Commonly Used In Chemical Processing Industries For Distillation And Absorption Processes. |

| Shape | Various Shapes Like Saddles, Rings, Or Grids. |

| Size | Typical Sizes Range From 10 Mm To 50 Mm. |

| Quantity | Sold In Bulk Quantities Based On Weight Or Number Of Pieces. |

| Durability | Highly Durable And Resistant To Corrosion. |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Chemical Engineering Equipment |

| Material | Stainless Steel |

| Color | Silver |

| Packaging | Standard Packaging |

| Usage | Separation And Purification Processes |

| Size | Various Sizes Available |

| Shape | Cylindrical |

| Weight | Varies Based On Size |

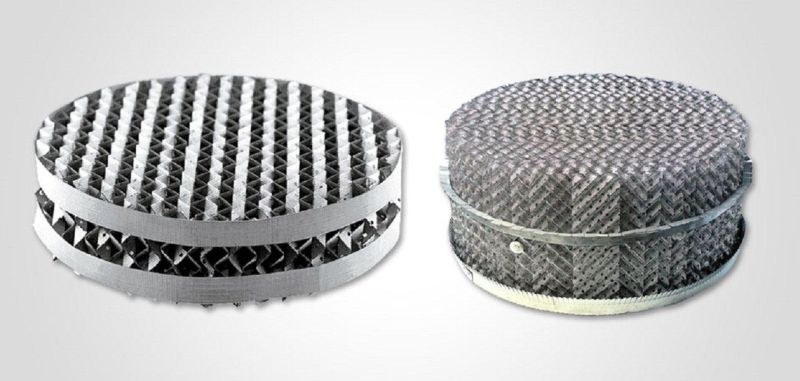

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Structured Packing |

| Color | Silver |

| Packaging | Standard Packaging |

| Application | Chemical Processing |

| Shape | Structured |

| Durability | Highly Durable |

| Maintenance | Low Maintenance Required |

| Business Type | Manufacturer, Exporter, Supplier |

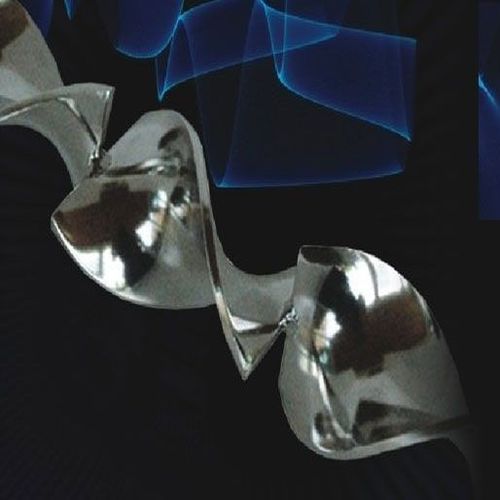

| Application | Mixing Products Into Water Or Water-like Fluids,Used For Low Viscosity |

| Material | SS - 316 |

| Model Type | Blade Design Mixer |

| Viscosity Range | Less Than 1500 Cps |

| Reynolds Number | Greater Than 500 |

| Size Range | 1/2 |

| Model | SW-SMx-01 |

| Model Type 2 | Helical Design Mixer |

| Application 2 | Used For High Viscosity Blending And Slow Fluid Movement |

| Material 2 | SS - 316 |

| Viscosity Range 2 | Greater Than 1500 Cps |

| Reynolds Number 2 | Less Than 500 |

| Size Range 2 | 1/2 Inch |

| Application Areas | Epoxy Blending, Fruits Into Yogurt, Cookies Into Ice Cream, Thermal Homogeneity, Slurry Suspension, Folding/stripping |

| Customer Benefits | Excellent Mixing And Dispersing, Compact Designs, Reduced Product Degradation, Mixing Of Sensitive Products, No Deposits And Blockages |

| Advantages | High Level Of Mixing Efficiency, Low Energy Consumption, Easy Installation, Available In All Standard Pipe Sizes |

| Industries Served | Pulp And Paper Processing, Pharmaceuticals, Oil Refining, Petrochemicals, Food Processing, Natural Gas Processing, Water And Waste Water Treatment |

Model Type – 1: Blade Design Mixer

-

Mixer Type: SS – 316 Material

-

Viscosity Range: Less than 1500 cps

-

Reynolds Number: Greater than 500

-

Size Range: ½" to 14"

-

Application: Mixing products into water or water-like fluids

SW-SMx-01: Used for low viscosity. The faster the fluid moves, the faster the mixing. Ideal for mixing products into water or water-like fluids.

Model Type – 2: Helical Design Mixer

-

Model: SW-SMx-02

-

Application: Used for high viscosity blending and when the fluid moves more slowly through the mixer

-

Material: SS – 316

-

Viscosity Range: Greater than 1500 cps

-

Reynolds Number: Less than 500

-

Size Range: ½" to 14"

-

Application Areas: Epoxy blending, fruits into yogurt, cookies into ice cream, thermal homogeneity, slurry suspension, folding/stripping

Customer Benefits

-

Excellent mixing and dispersing, even with widely differing fluid viscosities

-

Compact designs

-

Reduced product degradation due to very short residence time

-

Mixing of sensitive products under minimal shear stress

-

No deposits and blockages due to excellent cross-mixing

Advantages

-

High level of mixing efficiency – formation of byproducts is dramatically reduced

-

Low energy consumption

-

Easy installation

-

Available in all standard pipe sizes, and for open channel designs, available in any size with no upper limit

Industries Served

-

Pulp and Paper Processing

-

Pharmaceuticals

-

Oil Refining

-

Petrochemicals

-

Food Processing

-

Natural Gas Processing

-

Water and Waste Water Treatment

Design Calculations

Reynolds Number Formula:

Re = Dvρ/µ

Number of Elements Required:

-

Re < 10 → 24–36 elements

-

10 < Re < 100 → 18 elements

-

100 < Re < 1000 → 12 elements

-

1000 < Re < 10000 → 6 elements

-

Re > 10000 → 4 elements

Pressure Drop Calculation

ΔP = 3.061 × 10⁶ × f × n × smxpx(u)² × E

G Value Calculation

G = v(hf × g × ρ / μt)

Pipe Diameter (D in meters)

D = √(4Q / πv)

| Business Type | Manufacturer, Exporter, Supplier |

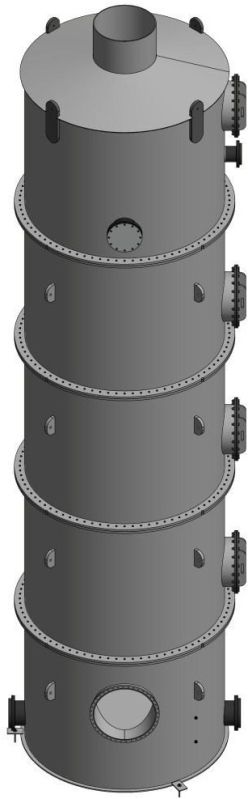

| Type | Stripping Column |

| Material | All Stainless Steel (SS304 / SS316) |

| Design | Tray Columns And Packed Columns |

| Internal Components | Mist Eliminator, Liquid Distributor, Bed Limiter, Packing Options, Packing Support Plate |

| Application | Removal Of Volatile Hydrocarbons, Water Purification, Solvent Recovery Systems, Chemical Process Stripping,VOC & Solvent Removal System For Industrial Applications |

| Key Features | Tailored Design, High VOC Removal Efficiency, Engineered Internals, Low Maintenance, Wide Material Choices |

Shreewire Stripping Columns are engineered systems designed for the efficient removal of volatile organic compounds (VOCs), such as benzene, toluene, xylene, and low-boiling solvents like methanol and ethanol from water streams. These columns are vital in industries requiring liquid purification or solvent recovery, including chemical, petrochemical, oil & gas, and wastewater treatment sectors.

Each column is configured based on process requirements and fluid composition, and is available in two main designs: Tray Columns and Packed Columns.

Tray Column DesignTray columns (also known as plate columns) are among the most widely used mass transfer devices in industrial separation. The number of trays and stages is precisely determined based on required separation efficiency and product purity.

Types of Trays Offered:

-

Sieve Tray

-

Bubble Cap Tray

-

Moving Valve Tray

-

Fixed Valve Tray

Key Benefits:

-

Modular construction for easier maintenance

-

Can be partially replaced with packing to debottleneck capacity

-

Designed for excellent vapor-liquid contact

Material of Construction (MOC):

-

All Stainless Steel (SS304 / SS316)

Packed columns provide high surface area for enhanced vapor-liquid interaction, resulting in greater separation efficiency per unit height compared to tray columns. Ideal for processes requiring compact column design and low-pressure drop.

Internal Components:

-

Mist Eliminator (Demister Pad)

-

Knitted wire mesh pad ensures 99%+ droplet separation down to 5 microns

-

Low-pressure drop (approx. 25 mm WC)

-

Maintenance-free and easy to install

-

-

Liquid Distributor

-

Ensures uniform liquid distribution across the packed bed

-

Prevents maldistribution, flooding, and inefficient mass transfer

-

-

Bed Limiter

-

Prevents displacement or fluidization of packing under high vapor load

-

Mounted on top of the packing layer

-

-

Packing Options

-

Random Packing: Metal/Plastic types (e.g., Raschig rings, Pall rings)

-

Maximizes surface-to-volume ratio, minimizes pressure drop

-

-

Structured Packing: Corrugated, honeycomb-type shapes

-

Precisely engineered to allow maximum surface area with low resistance

-

Suitable for high-efficiency, low-pressure operations

-

-

-

Packing Support Plate

-

Supports the weight of the packed bed

-

Designed with large open area to maintain uniform liquid and vapor flow

-

Prevents flooding and ensures mechanical integrity

-

Material of Construction (MOC):

-

All Stainless Steel (SS304 / SS316)

-

PP (Polypropylene) – for specific chemical resistance needs

-

Removal of volatile hydrocarbons and chlorinated solvents

-

Water purification and effluent treatment

-

Solvent recovery systems

-

Chemical process stripping and regeneration units

-

Tailored design with tray or packed configuration

-

High VOC removal efficiency

-

Engineered internals for optimal gas-liquid contact

-

Low maintenance and robust construction

-

Available in wide material choices for corrosive or high-temperature services

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Grid |

| Color | Silver |

| Size | Standard Size |

| Weight | Lightweight |

| Durability | Durable |

| Business Type | Manufacturer, Exporter, Supplier |

| Number Of Flower | Tower Packing |

| Material | Metallic Or Ceramic |

| Packaging Type | Silver |

| Packaging | Box Or Pallet |

| Application | Chemical Processing Or Gas Scrubbing |

| Shape | Random Or Structured |

| Size | Various Sizes Available |

| Quantity | Typically Sold In Bulk |

| Durability | Highly Durable |